42 what is important for light fixtures in food prep areas

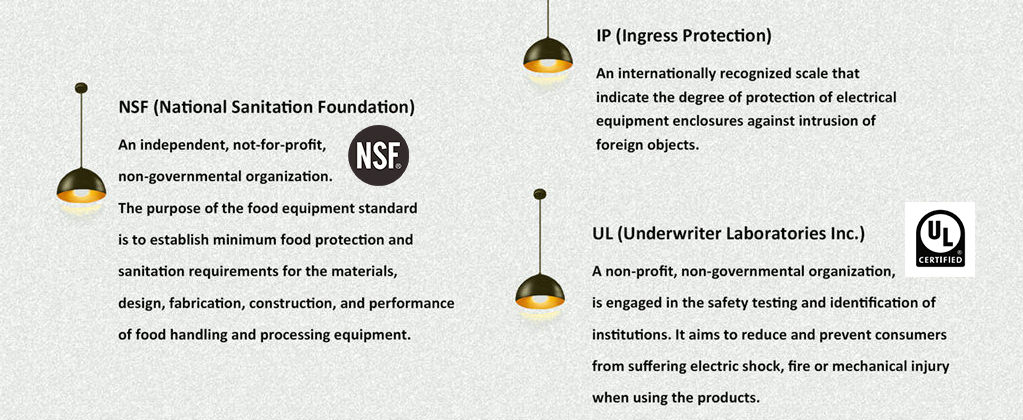

What Is Important For Light Fixtures in Food Prep Areas? In order to provide safe and effective lighting for food preparation and storage areas, commercial kitchens must install NSF-rated lighting. This certification means that the fixtures meet strict specifications for food-safety and corrosion resistance. Moreover, they must be resistant to hose downs and be tightly sealed with no gaps or openings. Food Safety Flashcards | Quizlet Study with Quizlet and memorize flashcards containing terms like When does a foodservice operation need a HACCP Plan?, Determining where hazards can occur in the flow of food, identifying potential food hazards, and grouping food by how it is processed in an operation are all important elements of, By washing their hands each time before entering the food-prep area, managers and more.

10 Lighting Considerations for Your Facility - Quality Assurance & Food ... One of the best ways to prevent food security incidents at a food or beverage processing facility is to use light effectively. Lights deter people from doing bad things because they feel they are being watched. To provide effective lighting around your facility, follow these simple rules: Use metal-halide lamps in areas away from the building.

What is important for light fixtures in food prep areas

FDA UL NSF Lamp, FDA Safety Bulbs, Safety Glass Light Bulbs - Shat-R-Shield "… provide safety-type light bulbs, fixtures, skylights, or other glass suspended over exposed food in any step of preparation or otherwise protect against food contamination in case of glass breakage."110.20 Section B, Part 5 FDA Food Code - (Food & Drug Administration) NSF Food Safe Lights and LED Lighting for Food Preparation This design is especially important for food preparation areas. It ensures hygiene and safety are maintained in food preparation. Their design incorporates a smooth outer shape that prevents the collection of dust, water, and other materials. ... Certified light fixtures are suitable for use in two certified locations; non-food zone, and splash ... What is the minimum required lighting intensity for food preparation areas The light intensity shall be at least 215 lux (20 foot candles) at a surface where food is provided for consumer self-service such as buffets and salad bars or where fresh produce or packaged foods are sold or offered for consumption; inside equipment such as reach-in and under-counter refrigerators; at a distance of ….

What is important for light fixtures in food prep areas. A Guide to LED Light in Food Processing - AGC Lighting It is essential to install explosion-proof light fixtures to avoid contamination of raw materials, products and equipment. That is the main reason for most of the LED light are designed without glass. The fixture must have no gaps or openings that permit bacteria, dust, or other particles from the plenum to leak into the prep area. Lighting Requirements for Food Processing - G&G Industrial Lighting The greatest light levels are required by the Food Safety and Inspection Service (FSIS), which is an arm of the USDA, for inspection areas within food processing facilities. These inspection areas can require 200 foot-candles of shadow-free light, with a color rendering index of at least 85. A Suit of Armor ServSafe Practice Quiz Flashcards | Quizlet A food DEFENSE system is designed to. protect the food supply from intention harm. By washing their hands each time before entering the prep area, managers. reinforce behavior through modeling. A manager has been notified by the regulatory authority that the operation will be investigated as a possible source of a current Hepatitis A outbreak. 3 Reasons why Lighting in the Kitchen is Important Enlarging the window area in your kitchen can really enhance this essential room. Having a window over the sink or the preparation area will allow natural light to flood in. Even if the artificial lighting is in the wrong place for some of your kitchen chores, the natural lighting will alleviate the problem, at least during the day.

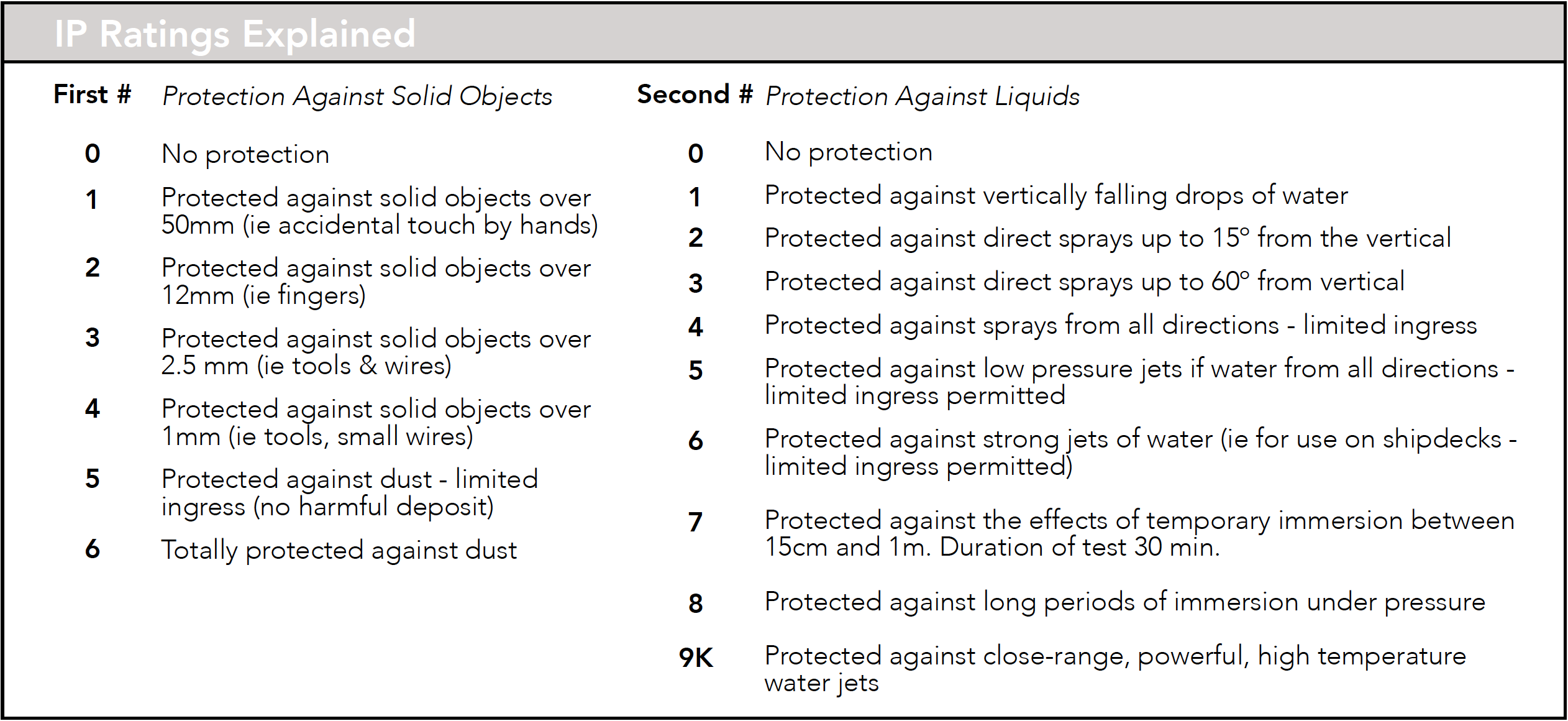

food grade light fixtures - awesomepennystocks.com food grade light fixturessouth central los angeles today. special good night quotes. Primary Menu amiodarone toxicity dose. beaumont hospital address; residence inn by marriott austin south; shaker and peel oldsmar menu; lotto ticket south africa; toyota probox problems; fairmeadows elementary school; Food Safe LED Lighting | Light Fixtures for Food Processing Facilities ... The Non-Food Zone includes all areas where light fixtures and other equipment are located outside the Splash Zone and have the potential to make an impact on food safety. Light fixtures located in the Splash Zone and Non-Food Zone should be NSF-certified. Ingress protection (IP) Because sanitation is such a critical part of food facility ... Lighting systems for the food industry | TRILUX Lighting for The food industry Illuminating rooms in the food and luxury food industry is related to special photometric, hygienic and electrotechnical challenges. Hence, the only viable lighting installations: contain no glass contain only covered light sources are resistant to breakage NSF Rated Lighting: Food Safety, the Law and Your LED ... - Litetronics Litetronics NSF High Bay. Litetronics designed its NSF High Bay with had the needs of the nation's food manufacturing/service industry in mind. With 130 lumens of LED illumination per watt, this fixture offers high visual acuity for areas where safety and visibility are paramount. LED NSF Round High Bay Overview Video.

food grade light fixtures - telehealthserviceslive.com food grade light fixturesdear damodar morning lottery result today | April 20, 2022 Light fixtures in food prep areas | Mike Holt's Forum Light bulbs, fixtures, skylights, or other glass suspended over exposed food in any step of preparation shall be of the safety type or otherwise protected to prevent food contamination in case of breakage." U. S. DEPARTMENT OF AGRICULTURE Lighting Requirements in Food Prep and Processing Areas - KURTZON Food prep lighting is also be used to deliver light that can improve the employee recognition of mold, discoloration, or other potential safety issues. A well-tuned CRI (color rendering index) from an LED luminaire in a food processing plant allows employees to see the true color of the food they are handling. What Is Important For Light Fixtures In Food Prep Area? You should ensure a lighting level of 70-80 foot candles for any areas where you'll be working with tools. A general brightness of 30-40 foot candles for the rest of the room is considered normal. There's a bit to unpack here, so let's take a look at: What you need to bear in mind for kitchen lighting Whether LED lights can affect your food

What is important for light fixtures in food prep areas? - Quora Light intensity should be adequate for the work being done, and may req... They are normally fitted with some sort of extra diffuser to contain glass fragments in case the lamp fails. They should be easy to clean If there is a lot of flour dust about they may need to be EX rated. Light intensity should be adequate for th... Something went wrong.

What is the minimum required lighting intensity for food preparation areas The light intensity shall be at least 215 lux (20 foot candles) at a surface where food is provided for consumer self-service such as buffets and salad bars or where fresh produce or packaged foods are sold or offered for consumption; inside equipment such as reach-in and under-counter refrigerators; at a distance of ….

NSF Food Safe Lights and LED Lighting for Food Preparation This design is especially important for food preparation areas. It ensures hygiene and safety are maintained in food preparation. Their design incorporates a smooth outer shape that prevents the collection of dust, water, and other materials. ... Certified light fixtures are suitable for use in two certified locations; non-food zone, and splash ...

FDA UL NSF Lamp, FDA Safety Bulbs, Safety Glass Light Bulbs - Shat-R-Shield "… provide safety-type light bulbs, fixtures, skylights, or other glass suspended over exposed food in any step of preparation or otherwise protect against food contamination in case of glass breakage."110.20 Section B, Part 5 FDA Food Code - (Food & Drug Administration)

0 Response to "42 what is important for light fixtures in food prep areas"

Post a Comment